MANUFACTURING & FABRICATION

Warfab has a 42 acre site with both machining and welding facilities capable of handling large fabrications, repairs, and new equipment components. Our capabilities include up to 90 tons of lifting loads to heights of 40 foot.

We have a unique skillset to manufacture complex products that require a multiple of machining and welding processes.

Welding Capabilities

Our metal fabrication shop provides quick and accurate construction of large capacity structures and assemblies. We offer customized metal fabrication, welding, and grinding services in all grades of carbon steel, alloy, and stainless materials using SMAW, FCAW, SAW, GMAW and TIG processes.

Our thicker cross-sections and heavier gauge alloys allow us to create larger capacity fabrications than traditional metal fabricators.

OUR FABRICATION SERVICES:

- Conventional or exotic alloy fabrication

- Pressure vessels and tanks

- Multi-torch and plasma cutting

- Large in-house steel inventory

- Heavy forming capabilities

- Plate rolls

- Press brake

- Angle and pipe rolls

- High temperature fabrication

- Bore welding machines

- Tube/pipe weldments, structural shapes, and plate fabrication

Post-Welding Services

- We can also provide comprehensive post-welding services such as:

- Stress relief

- Blasting and Painting

- Coating

- Large machining

Our Fabrication Facility

- 90 ton lift capacity

- 40 foot hook head room

- CNC 3 torch burn table, up to 8” thick plate cuts

- Plasma / Oxy table

Certifications

- Maintain ASME U Stamp and R Stamp certifications

- ISO 9001:2015, ABS, DNV

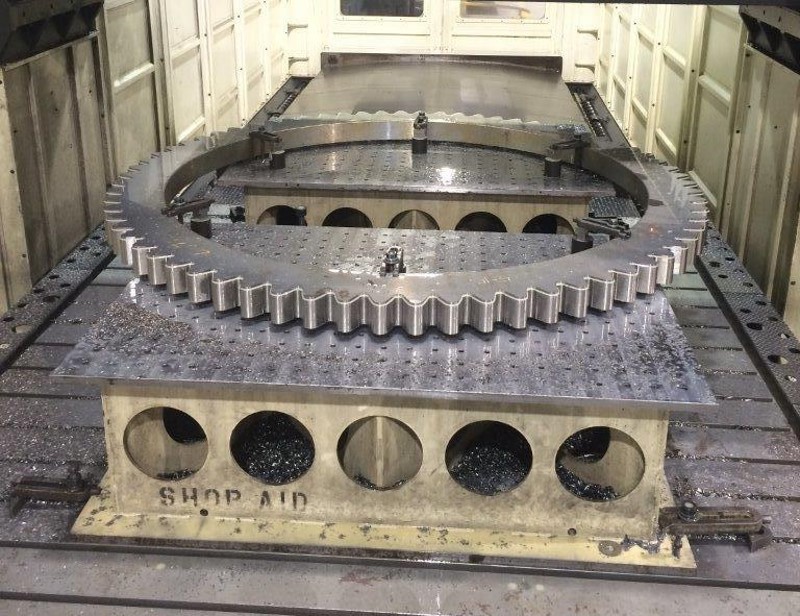

MACHINING CAPABILITIES

In today’s world, components are requiring an ever-increasing complexity in design and accuracy. Warfab has the experience, resources, and equipment to support a wide variety of machining requirements.

We utilize state-of-the-art equipment to perform all types of machining services, such as machining of medium to high complexity components, in-house welding, low and medium volume production, and expertise in multipart mill and lathe components.

Our equipment includes horizontal and vertical boring mills, lathes, shapers, surface grinders, milling machines, and radial drill press.

We have documented ISO internal quality control procedures that are initiated from the receipt of your purchase order and extend through the entire manufacturing processes. This helps to produce high quality products.

Our Machining Facility

- 15,000 Sq Ft facility

- Our CNC Lathes can handle workpieces up to 16.75” in diameter and 45” in length

- Our CNC Mills include table sizes up to X-234”, Y-140”, Z-40” with a 35,000 lb load capacity

- Our CNC Horizontal 4-axis Boring Mill include sizes up to X-78”, Y-59”, Z-60” with a 19.625 quill feed and 13,860 lb load capacity

- Our Vertical Turning Lathes have a capacity up to 144” diameter and 9’ height